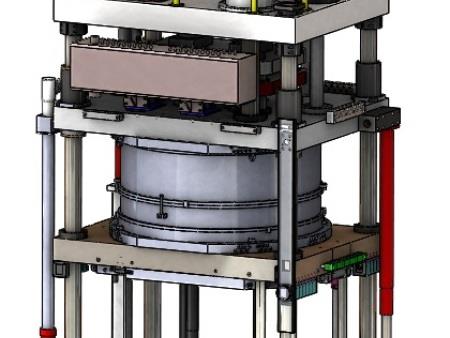

Counter pressure casting machine is also called pre-press forging and pressure difference forging. This is basically a low-pressure casting. The metal-type casting shell has a sealing cover. The air is compressed into the raft and the hood, but the working pressure in the ram is slightly higher, so that the metal material in the crucible is at a pressure difference. The metal tube is filled with a riser tube under the effect and crystallized under working pressure. This is a fusion of low pressure casting and two types of forging of crystals under working pressure. Some of the differential casting machine castings have high internal quality specifications and are expected to crystallize at higher working pressures, but usually the working pressure of the crystals during low pressure casting cannot be large. Therefore, the development trend is the pressure difference method....

Differential pressure casting machine is also called pre-press forging and pressure difference forging. This is basically a low-pressure casting. The metal-type casting shell has a sealing cover. The air is compressed into the raft and the hood, but the working pressure in the ram is slightly higher, so that the metal material in the crucible is at a pressure difference. The metal tube is filled with a riser tube under the effect and crystallized under working pressure. This is a fusion of low pressure casting and two types of forging of crystals under working pressure.

Some of the differential casting machine castings have high internal quality specifications and are expected to crystallize at higher working pressures, but usually the working pressure of the crystals during low pressure casting cannot be large. Therefore, the development trend is pressure drop method low pressure casting. The whole process of the processing process is to seal all the resistor holding furnace and the metal mold casting, and the air pressure in the sealing hood is very large, such as 600 kPa. At this time, the working pressure inside the metal mold and the pot is increased. The same, the metal material liquid is not easy to rise, and then the metal material liquid fills the working pressure of 60 kPa, and the metal material liquid will rise to fill the cavity. A metal material solution in a metal mold is also condensed by crystals under pressure. This type of approach gives the casting a higher density of crystal structure and improves the physical properties of the casting. According to the material, this type of processing technology is compared with the usual forging method, which increases the compressive strength of the casting by about 20% and the tensile strength by about 60%. However, the equipment is more plentiful, the actual operation is inconvenient, and it can only be used when required.

(2) Differential pressure casting machine vacuum pump low-pressure casting For thick-walled or complicated large and medium-sized castings, when the above-mentioned low-pressure casting processing technology is used, it is also impossible to consider, and vacuum pump low-pressure casting is very easy to handle. Its equipment is similar to the pressure differential method for low pressure casting. Before the pouring, the vapor in the cavity is extracted and then poured. At this time, the pouring rate can be increased, and the defects such as air oxidation and venting holes are not easily caused.