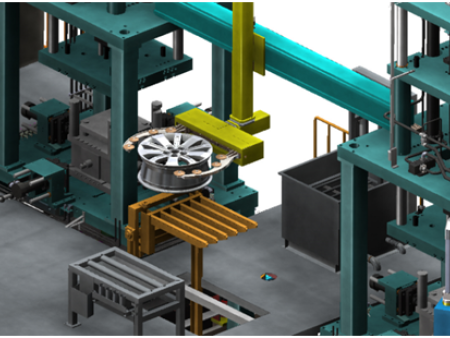

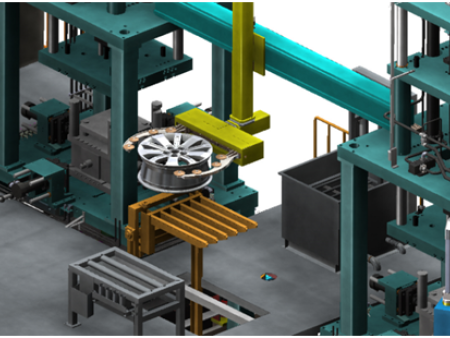

Automatic low pressure casting machine

Home>company's product > Full field automation system MES system

The processing and manufacturing automation technology of the processing plant is a process in which all or a part of the production and processing of the goods is carried out by industrial equipment, instrument panels and automation technology equipment without ginseng in actual operation. Processing plant manufacturing automation technology refers to the processing of all or a part of the production and processing of goods by industrial equipment, instrument panels and automation technology equipment without the need for ginseng in actual operation. Automatic low-pressure casting machine manufacturing automation technology covers a wide range of production process automation technology, raw material storage and conveyor automation technology, product quality inspection automation technology, assembly line automation technology and design...

The processing and manufacturing automation technology of the processing plant is a process in which all or a part of the production and processing of the goods is carried out by industrial equipment, instrument panels and automation technology equipment without ginseng in actual operation. Processing plant manufacturing automation technology refers to the processing of all or a part of the production and processing of goods by industrial equipment, instrument panels and automation technology equipment without the need for ginseng in actual operation.

Automatic low-pressure casting machine manufacturing automation technology covers a wide range, including production process automation technology, raw material storage and conveyor automation technology, product quality inspection automation technology, assembly line automation technology and design products and enterprise production management information resource management automation technology Wait.

Under the standards of manufacturing automation technology, the key to human responsibility is to control system design, assembly, adjustment, inspection, supervision of processing, quality management, and regulation and maintenance of automated machinery and equipment. China's machinery belongs to non-sustainable production and manufacturing, and it has a lot of difficulty in establishing automation technology with the continuous production and manufacturing of chemical plants, metallurgical industry and light industry. 30 New Century 65 era, with the automatic identification of instrument panel technology, electronic information technology, especially in the development of computer hardware technology, the emergence of digital control CNC lathes, CNC machine tools and industrial robots, etc., mechanical equipment industry automation technology has a new Improvement.

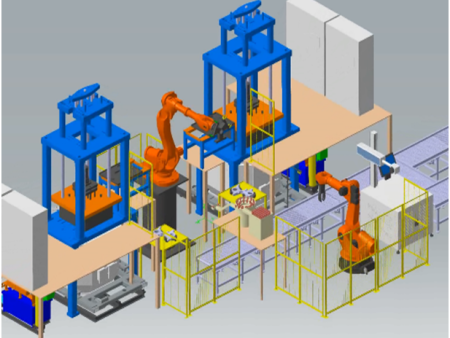

Mechanical equipment industry automation technology from the scale of operation, there are stand-alone version of automation technology, automated production lines, rigid production lines, automation technology production workshops and automation technology processing plants. From the beginning of the 90th era, this integrated auxiliary design and manufacturing system software (ICAMS) with the overall goal of establishing optimal control of the process has emerged. It flexibly uses electronic information technology to form a detailed organic chemistry process for market demand analysis, ordering, designing products, production planning and supervision of raw material components in advance preparation, production processing, assembly line, inspection, commodity testing and packaging delivery. Manufacturing system software (see figure). Because most of the unit's manufacturing management can rely on the role of several multi-faceted electronic computers, to establish a more advanced form of automation technology (including the design information content search and measurement, planning solutions, graphic ideas, manufacturing process flow allocation , data processing methods and storage, etc., which not only greatly simplifies the entire process of the complicated management methods of the mechanical factory, but can further improve the management level of the company.

Stand-alone automation technology relies on fully automated machines and automata to build a subset of automation technologies for manufacturing themed activities. The fully automatic machine can fully perform the basic safety operation of the process flow. When one cycle time is completed, the automatic parking is required. However, when starting from the beginning of another cycle time, it is necessary to start or perform some auxiliary safety work. When the equipment is started, the person can leave the machine to actually operate another CNC lathe, which in turn creates a standard for establishing multi-machine care. The automatic machine is a working machine with the necessary adjustment of emotions. In addition to product quality inspection and bare metal adjustment, it can fully establish the entire work of the production and processing cycle system.

The fully automatic low-pressure casting machine is interconnected by steel transmission equipment and has continuous production of automated mechanical system software with consistent handling equipment. In the automated production line, no one is involved in the actual operation. The burden of human beings depends only on regulation, regular adjustment and the removal of cutting tools. The automated production line has been used in many aspects of Chinese machinery. It can perform hardware processing of parts and components, and can process blank processing, metal surface treatment, electric welding, metal surface treatment, commodity assembly line and packaging. The use of automated production lines enables all processes to maintain a high aspect ratio continuity, significantly reducing manufacturing cycle time, reducing the number of crafts in the total number of crafts and simplification planning, so that the delivery route of goods exceeds the minimum limit. .

Rigid production lines can be integrated into a variety of small, high-volume production automation system manufacturing system software, namely flexible manufacturing systems. Applying group technology to combine parts with similar feature (specification, processing technology, etc.) into two sets of parts. This type of component can use the block diagram design scheme, according to the specifications must be filled in; you can also use the software to save the pattern into data, draw the engineering drawings when the design is changed, or immediately put this statistical data Typed into the CNC machine tool of the CNC lathe, this kind of system software can automatically determine the production and processing standards of the CNC lathe, the special tools for application and the medium-moving rail. If two sets of CNC lathes plus mechanical equipment transfer equipment and automatic assembly machinery are connected into a production line, it is possible to form a programmable automation technology manufacturing system software according to the design plan → processing technology → production processing → assembly line. . When the two sets of parts are manufactured in large quantities, they can only be fully adjusted according to the regulations, and just start to manufacture another set of parts. This means that the programmable production line can be adjusted and adjusted, that is, the rigid production line. This kind of production line can not only integrate the characteristics of fast upgrading of products, but also reduce the cost and cost by using the efficiency of the production line.

The automatic low-pressure casting machine production workshop and the automation technology processing factory take the automated production line flexible manufacturing system as the basic automation technology production workshop, plus the information management, enterprise production management automation technology, and the automation technology manufacturing and processing plant. It is an advanced way of manufacturing automation technology, also known as automation technology or no one pharmaceutical factory. This is an integrated automation technology processing plant of the motion control system. It uses CNC lathes, industrial robots, in-plant data acquisition system software, and intelligent system monitoring systems to establish the entire automation technology of the processing plant. Only a few inspections and defenses are required. Personnel, fully implement the electronic computer grade classification operation, and use the integrated system software to program and coordinate each module steel in the factory.