Aluminum alloy low-pressure casting machine equipment can be installed immediately on the furnace edge to establish online degassing! Furnace-mounted elevators for dehydrogenation and decontamination machines XPC400 is a complete set of on-line degassing and dehydrogenation equipment with electric ball screw lifting system installed along the fixed fixed position. It is not easy to attach during work. Occupying the area, it does not endanger all production process procedures. It is proposed that the customer pre-embed the degassing tank at the time of purchasing the new furnace for convenient transportation and degassing equipment in the middle and later stages; the degassing medium of the machine is usually applied. 99.996% of hydrogen or argon that has been cleaned and cleaned (considering cost...

Aluminum alloy low-pressure casting machine equipment can be installed immediately on the furnace edge to establish online degassing!

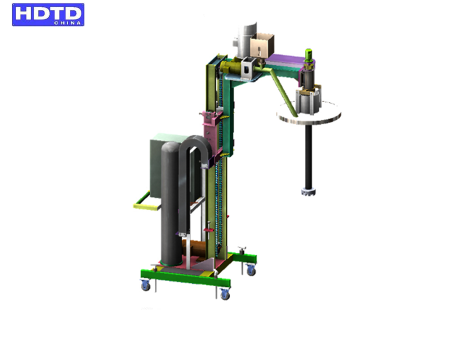

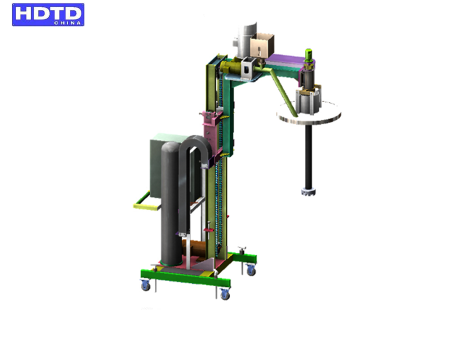

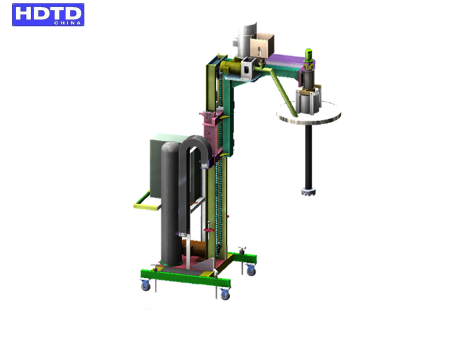

Furnace-mounted elevators for dehydrogenation and decontamination machines XPC400 is a complete set of on-line degassing and dehydrogenation equipment with electric ball screw lifting system installed along the fixed fixed position. It is not easy to attach during work. Occupying the area, it does not endanger all production process procedures. It is proposed that the customer pre-embed the degassing tank at the time of purchasing the new furnace for convenient transportation and degassing equipment in the middle and later stages; the degassing medium of the machine is usually applied. About 99.996% of hydrogen or argon is cleaned and cleaned (it is strongly recommended to use hydrogen in consideration of cost).

XPC400 degassing machine equipment is a high-efficiency aluminum liquid environmental protection equipment designed for degassing, dehydrogenation and slagging of centralized melting and holding furnace. The structure type is immediately installed on the furnace edge of the melting furnace, according to the customer. The size of the furnace wall and the appropriate length of the interior wall and its suitable elevator schedule can be said to be a complete set of environmentally friendly equipment designed according to the furnace design. It occupies a small area, compact structure, convenient operation, electric ball screw lift easy to replace high-purity graphite parts, excellent basic principle of degassing, can reasonably remove aluminum without harming production and casting processing technology Chlorine and impurities in the liquid, showing clean pouring aluminum.

It can be used in: degassing and decontamination of molten holding furnaces, concrete wells, etc.

Characteristics of degassing machine equipment:

1. Low price and good quality, low cost, good use of degassing, small floor space, convenient positioning of mobile modules, accurate positioning, no need to disassemble and continue to apply, suitable for online applications;

2. The electric ball screw lift equipment (set with the travel switch) makes the precise positioning of the motor rotor accurate and convenient to replace;

3, easy to operate, select the actual operation of the button, degassing time can be set (0 ~ infinitely long adjustable), there is automatic / manual control method, usually apply automatic control system can only, for online degassing time Set to infinite length only;

4. When the set degassing time is carried out, the rotor of the motor will stop, the air supply will be automatically turned off, the suspension wall will be fully automatic, and the display light will be turned off automatically, prompting the operator, and the safety factor is high; When the working pressure of the rare gas is lower than the set working pressure, the automatic alarm of the machine equipment prompts the actual operation staff to immediately remove the gas source;

5, the application of hydrogen or argon as a degassing medium, excellent basic principles of degassing, greatly reducing the degassing time, improve work efficiency, reduce the cost of refining, and have no environmental pollution to the natural environment, the office environment is greatly improvement of;

6. The controllability of the total flow of rare gases can be optimally set, which can greatly reduce the waste caused by bubbles and impurities, greatly improve the output rate and improve the physical properties of the castings;

7. Presenting the actual effect of smooth and repeatable degassing, if the customer establishes high-efficiency production and manufacturing, it does not endanger the process of manufacturing system;

8. There is no etch on the lining of the ladle or the boiler;

9. The separator can be selected; the effect of the separator is to stabilize the surface layer of the aluminum liquid during degassing and reduce the pollution in the treatment mode;

12. The wind turbine cooling equipment is included in the spindle bearing and motor of the machine. It can reasonably reduce the operating temperature of the spindle bearing and the motor and increase the service life.

12. Set emergency standby button, restart simple safety, firm structure, easy maintenance and low maintenance regulations.

The basic principles of hydrogen removal/degassing of machinery and equipment are:

According to the rotation plan of the high-purity graphite shaft and the rotor mixing aluminum liquid, the rare gas metered and tested is pressed into the aluminum liquid according to the rotor of the motor and sprinkled into fine bubbles to be evenly dispersed in the liquid-melt metal material. The gas partial pressure of the bubble is zero. Because the partial pressure of hydrogen in the aluminum liquid is high, the chlorine gas in the aluminum liquid continuously diffuses into the bubble, and a part of the non-metallic material in the aluminum liquid is sucked on the surface of the bubble, the unused chlorine gas and a part of the non-use. The rare gas bubble adhered by the metal material inclusions is up-regulated to the liquid level. After the treatment is completed, the high-purity graphite rotating rod is fully lifted up, and only the slag residue can exceed the purpose of removing hydrogen and air oxidation impurities. The machine has a small footprint and can be accurately positioned according to the actual location of the manufacturer. Rare gases can be presented by the gas supply management center in the form of steel cans placed next to the machine. The basic principle of the degassing is well-known, high efficiency and good use, does not harm the process of production and manufacturing system, can improve the purity of aluminum liquid in a short time, reduce the failure rate, improve the physical properties of castings, and improve the commodity. The ability to compete, it is beyond the traditional method of degassing.