Casting mold means that in order to obtain the structural shape of the part, the structural shape of the part is made in advance with other easily formed materials, and then the mold is placed in the sand mold, so that a cavity having the same structural size as the part is formed in the sand type. A fluid liquid is then poured into the cavity, and the liquid is cooled and solidified to form a part identical to the shape of the mold. Casting molds are an important part of the casting process. The casting mold refers to a mold used to form a casting in a casting forming process. The casting mold is matched with the casting process, mainly including gravity casting mold, high pressure casting mold (die casting mold), low pressure casting....

Casting mold means that in order to obtain the structural shape of the part, the structural shape of the part is made in advance with other easily formed materials, and then the mold is placed in the sand mold, so that a cavity having the same structural size as the part is formed in the sand type. A fluid liquid is then poured into the cavity, and the liquid is cooled and solidified to form a part identical to the shape of the mold. Casting molds are an important part of the casting process.

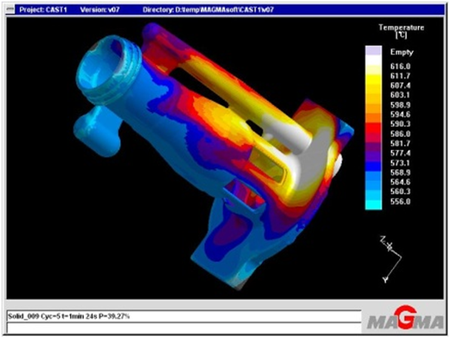

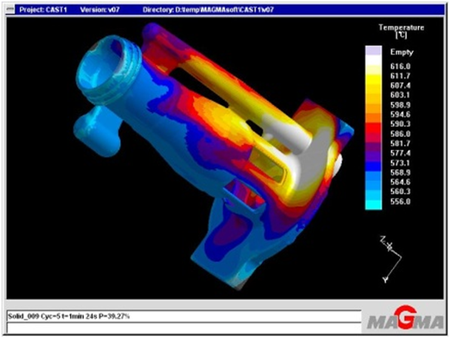

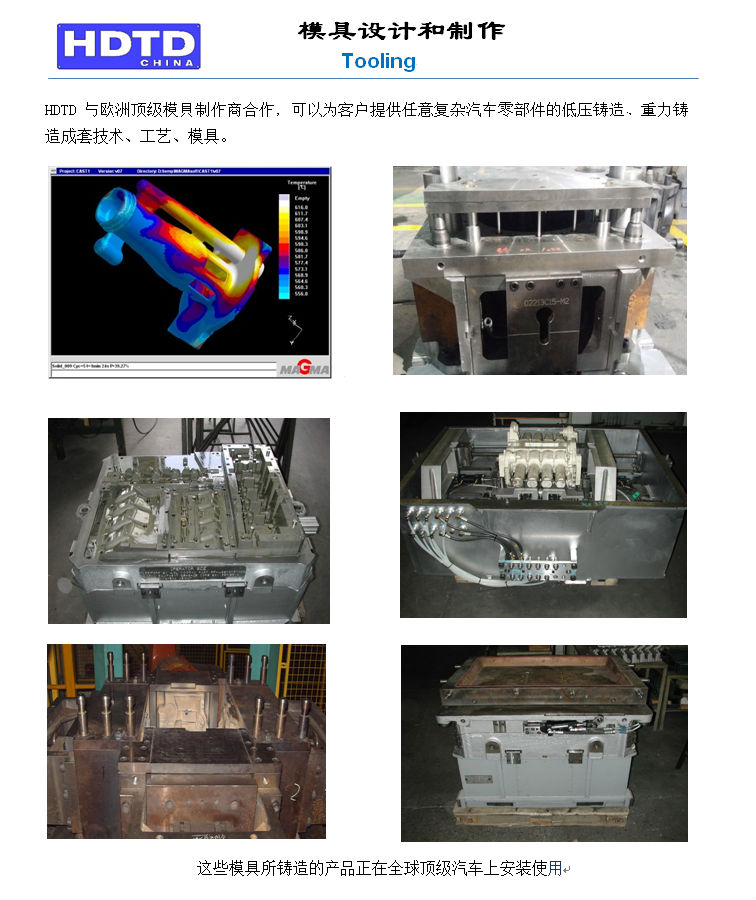

The casting mold refers to a mold used to form a casting in a casting forming process. The casting mold is matched with the casting process, mainly including gravity casting mold, high pressure casting mold (die casting mold), low pressure casting mold, and extrusion casting mold. Casting mold is one of the most important process equipment in casting production, which has a great influence on the quality of castings. The improvement of casting mold technology will be of great significance to improve the quality of castings, develop new castings and improve the near-net processing level. The advancement of casting mold technology will provide more precise, complex and high-quality castings for the pillar industries of automobiles, electric power, ships, rail transit, aerospace and other countries, and promote the overall level of China's manufacturing industry.

With the rapid development of industries such as automobiles, motorcycles, aerospace and other industries, casting molds are growing at a rate of more than 25% per year. The casting mold technology has made great progress, but it is represented by a large-sized aluminum alloy engine block. Complex die casting molds mainly rely on imports. China's automobile and motorcycle industry has entered a period of rapid growth, and the output has increased substantially for many years. It can be predicted that in the next 10 to 20 years, the production of casting molds in China will still gain strong momentum mainly from the automobile industry and grow at a high speed. In the context of energy saving and emission reduction, the increase in ferrous metal gravity casting molds will slow down, while aluminum-magnesium alloy die-casting molds, low-pressure casting molds and extrusion casting molds will increase substantially.

← Low pressure casting machine

No Information →