The quantitative casting furnace is a fashion trend that incorporates the rapid development trend of magnesium alloys, and fully utilizes the advantages of low-carbon environmental protection unique to magnesium alloys, and allows magnesium alloy products to be used in every corner to produce goods. At this stage, the magnesium alloy melting furnace of the series of products developed and designed by the enterprise thoroughly considers the processing technology regulations for the high safety factor of magnesium alloy handicrafts in the production and manufacturing, and the application is safer and cheaper. For the large, medium and small aluminum alloy profiles and zinc alloy material products factory, it is a top ten happy report, if the manufacturer presses the aluminum or zinc alloy of the factory...

The quantitative casting furnace is a fashion trend that incorporates the rapid development trend of magnesium alloys, and fully utilizes the advantages of low-carbon environmental protection unique to magnesium alloys, and allows magnesium alloy products to be used in every corner to produce goods.

At this stage, the magnesium alloy melting furnace of the series of products developed and designed by the enterprise thoroughly considers the processing technology regulations for the high safety factor of magnesium alloy handicrafts in the production and manufacturing, and the application is safer and cheaper. For the large, medium and small aluminum alloy profiles and zinc alloy material products factory, it is a top ten happy report. If the manufacturer replaces the melting furnace on the aluminum or zinc alloy die casting machine of the factory into the magnesium alloy produced by our company. The furnace, which aims to adjust the main parameters of the aluminum die-casting machine, can die-cast magnesium alloy products. Moreover, when the manufacturer wants to repair and manufacture the original goods, it is only necessary to replace the melting furnace and return it to be able to manufacture it successfully; after the renovation, it is more convenient to choose a smarter and do business.

Advantages of cost and cost The newly-developed magnesium alloy crafts event processing cost is only 40% higher than the cost of post-processing of aluminum alloy profiles and zinc alloy products, and the technical cost is improved, and the cost is more reduced. At the post-processing level of magnesium alloys, people can present a complete set of processing techniques and professional equipment to thoroughly deal with the worries of customers' adverse effects.

People show their intimate service of one-stop service to ensure the production of qualified magnesium alloy products for customers; let you produce the highest quality magnesium alloy products with the least cost, and get the maximum profit.

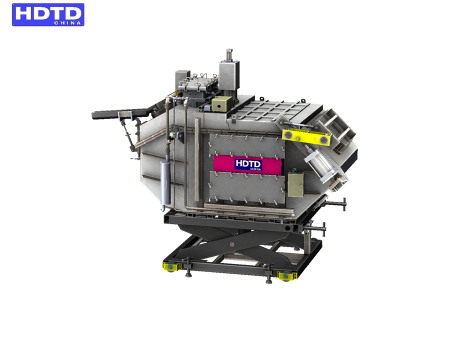

Series of products Cold chamber die casting machine supporting facilities Magnesium alloy melting furnace / manual and automatic two kinds of complete equipment categories:

A. Magnesium alloy melting furnace (manual / fully automatic) 1 set

B. Maintenance of steam cabinets (air source customer spare) 1 set

C. Electrical control cabinet 1

D. Double aluminum alloy composite plate crucible (installed in the furnace body) 1 hot room machine supporting facilities gasoline and diesel / gas / electric heater magnesium alloy furnace hot chamber machine supporting facilities magnesium alloy furnace shell and rear cover and other notes Stainless steel processing. Beautiful, temperature resistant and corrosion resistant. The feeding port adopts a flap and a double rocker horizontal drawing chamber. That is to say, when pulling the material, the plate should be pulled horizontally (at this time, the opening is small), and when the slag is slag, all the flaps (connected to the cross-plate) are rotated together (at this time, the opening is larger).

The heating components are selected from the software room, which is convenient for regular inspection and maintenance. In order to control the temperature, the 3 point chamber operation is carried out according to the thermal resistance in the melting chamber of the crucible, the greenhouse and the furnace.

Press the effusion tube on the side of the furnace and install the test liquid leakage device. There are 8 or so maintenance steam input pipes around the crucible to ensure that the maintenance steam is jointly distributed in the crucible.

Magnesium alloy furnaces use high-efficiency lightweight concrete refractory insulation materials and high-efficiency heaters. High thermal efficiency and good thermal insulation properties.